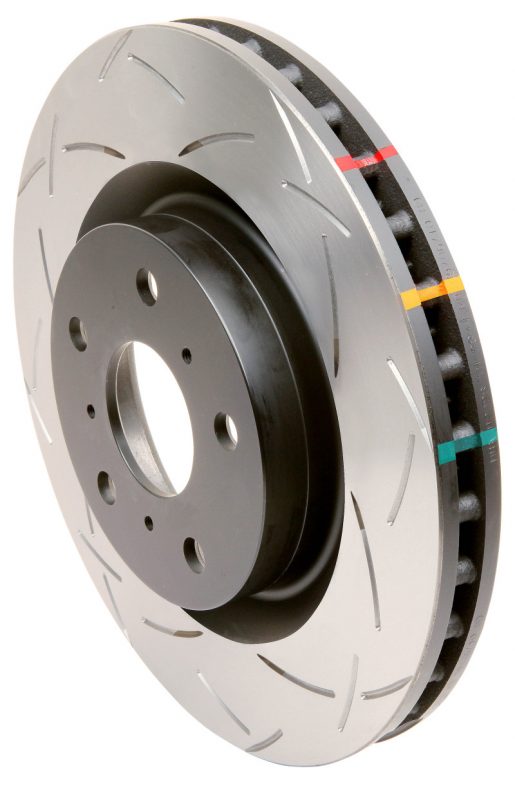

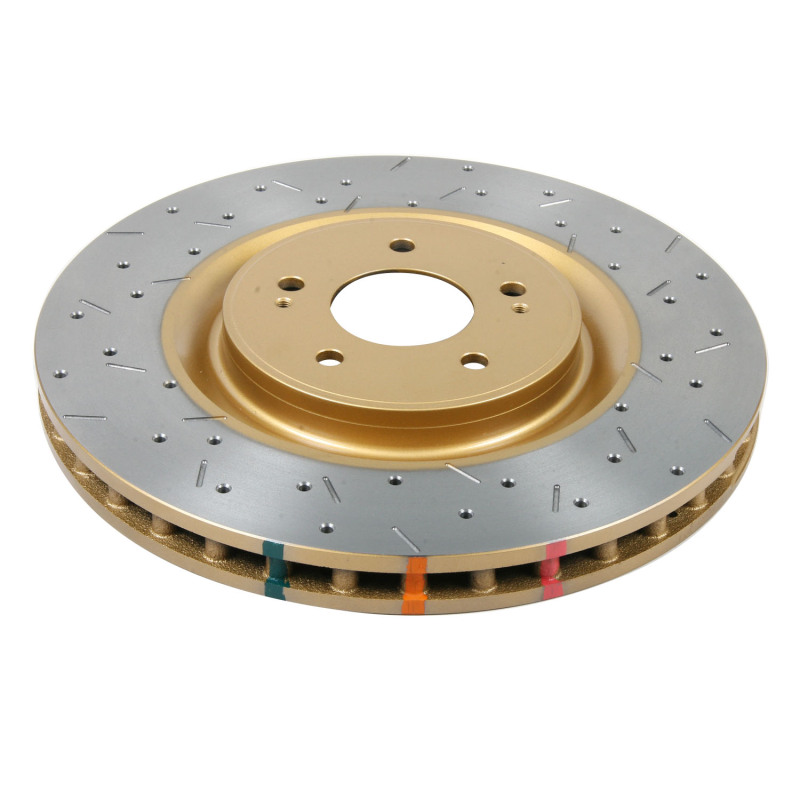

DBA’s 4000 Series T3 rotors feature our best technology and materials for maximum performance. High carbon & heat treated iron, patented Kangaroo Paw ventilation and Tri-symmetrical slotting makes for the perfect direct replacement rotor

- T3 Slot 48 precision CNC machined slots Tri-Symmetrical curve slots dampens the vibration harmonics or noise A quieter, responsive and smoother brake pedal feel. Increased number of out-gassing exit points for brake pad friction gasses to escape through Increases the consistency and effectiveness of every brake stop

- Universal slot design Eliminates the need for left and right discs

- Kangaroo Paw – 144 diamond and tear drop pillar ventilation system Increased surface area resulting in greater heat dissipation Minimises brake fade and increases braking effectiveness, Increased surface area resulting in greater heat dissipation Prolongs service life for both pads and rotors. Reduces mechanical damage and associated costs

- XG150 High Carbon Alloyed Iron An increase in thermal capacity property allows the rotor to handle constant extremes of heat over extended periods of time Minimises warping and cracking and prolongs the service life of the rotor. Special formulation designed to respond to DBA’s TSP process Minimises warping and cracking and prolongs the service life of the rotor

- Thermographic Temperature Monitoring Heat paint markings change colour at specific temperature thresholds Offers the driver a clear indication of peak braking temperatures. When temperature thresholds are exceeded paint markings will permanently change colours Allows the driver to monitor rotor fatigue and decide on rotor replacement

- Paint protection on non-friction areas Reduces corrosion Stops any unsightly rust formation

| Weight | 20 lbs |

|---|---|

| Dimensions | 15 × 14 × 3 in |

| Rotor Style | T-Slot Uni-Directional Slotted Rotor, Cross Drilled/Slotted Uni-Directional Rotor |

| Make | Model | Year |

|---|---|---|

| Make | Model | Year |

| Mitsubishi | EVO X | 2008-2015 |